- Home

- About Us

- Products

- Temperature

- Pressure

- Pressure Gauges

- Differential Pressure Gauge

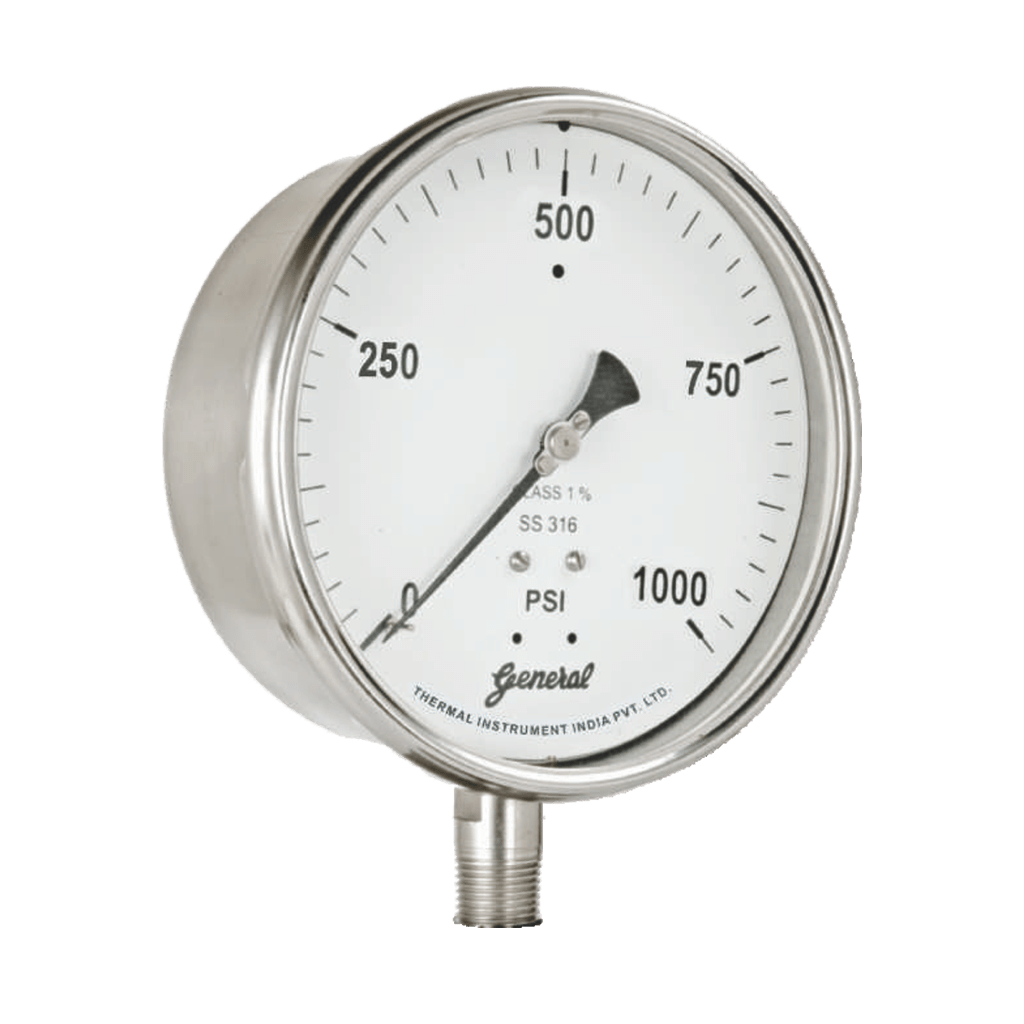

- Sandwich Type Diaphragm Seal for special application

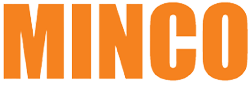

- Flush Diaphragm

- Extended Diaphragm Seal

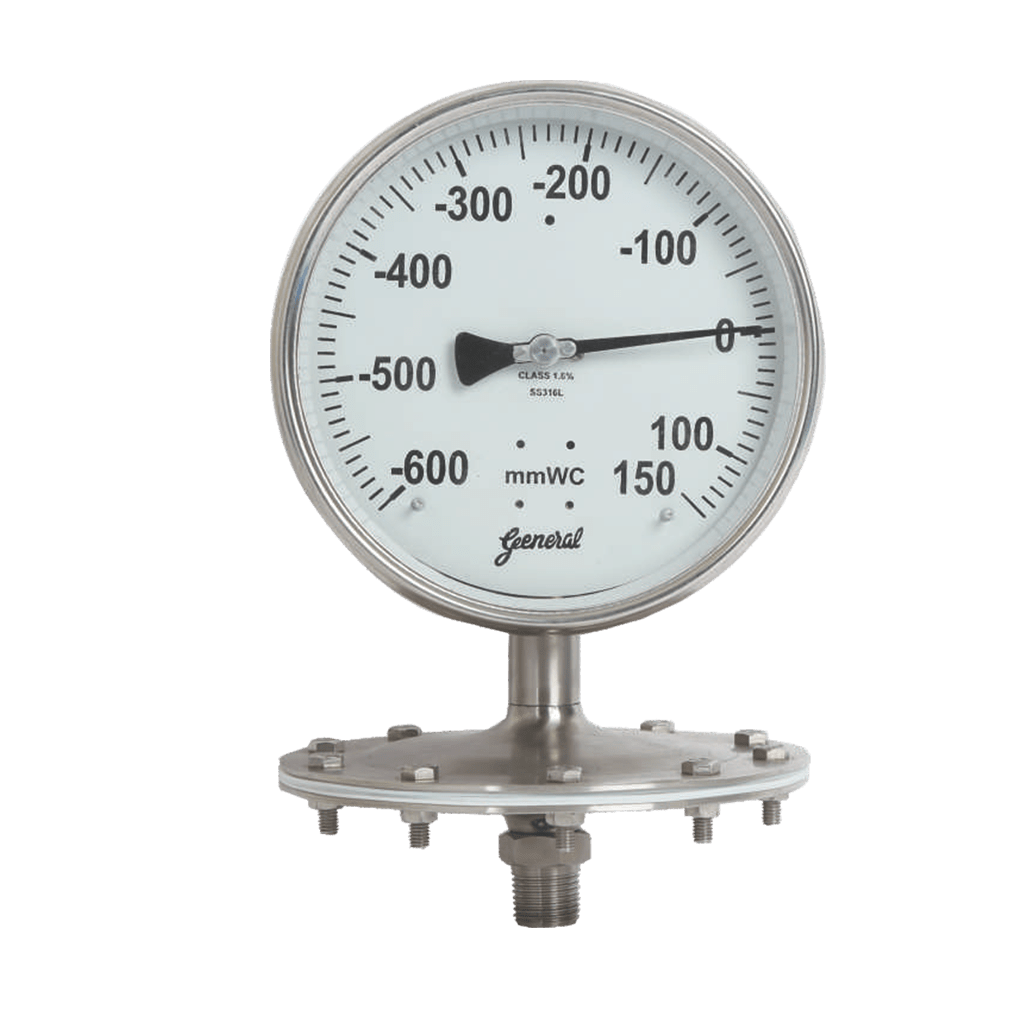

- Low Pressure Diaphragm Sensing Pressure Gauges

- Chemical/Diaphragm Seal Unit

- Safety Pattern – Solid Front Pr. Gauges

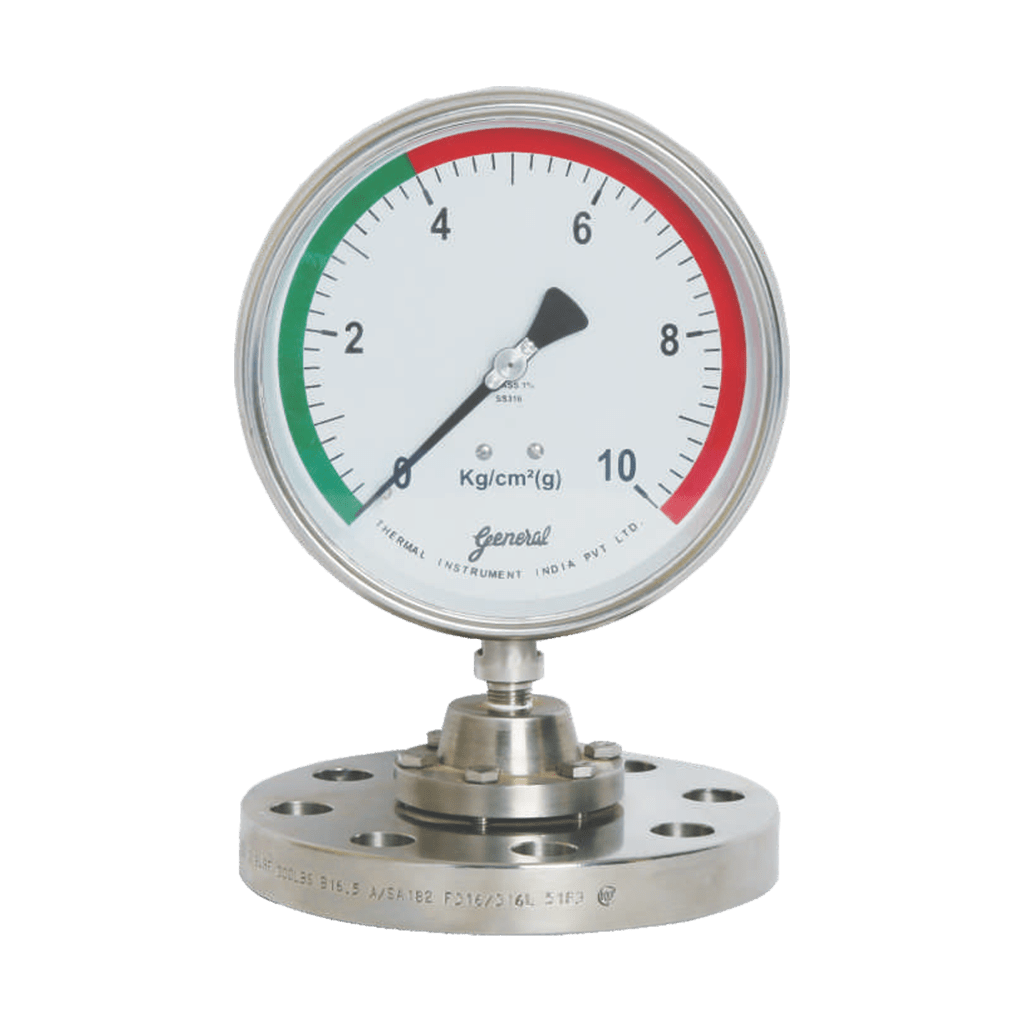

- Bourdon Sensing Pressure Gauges

- Pressure Transmitter

- Differential Pressure Gauges – Bellow / Diaphragm Type

- Intelligent single crystal silicon pressure /Differential pressure transmitter

- Flow

- Level Gauges

- Valves & Manifolds

- Career

- Blogs

- Contact Us