General Instruments Orifice Plate Assemblies With RTJ Holder

GIC is the leading Orifice Plate Assemblies With RTJ Holder Manufacturer in India providing reliable solutions for accurate pressure measurement to process industry worldwide.

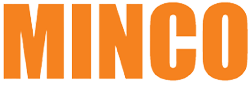

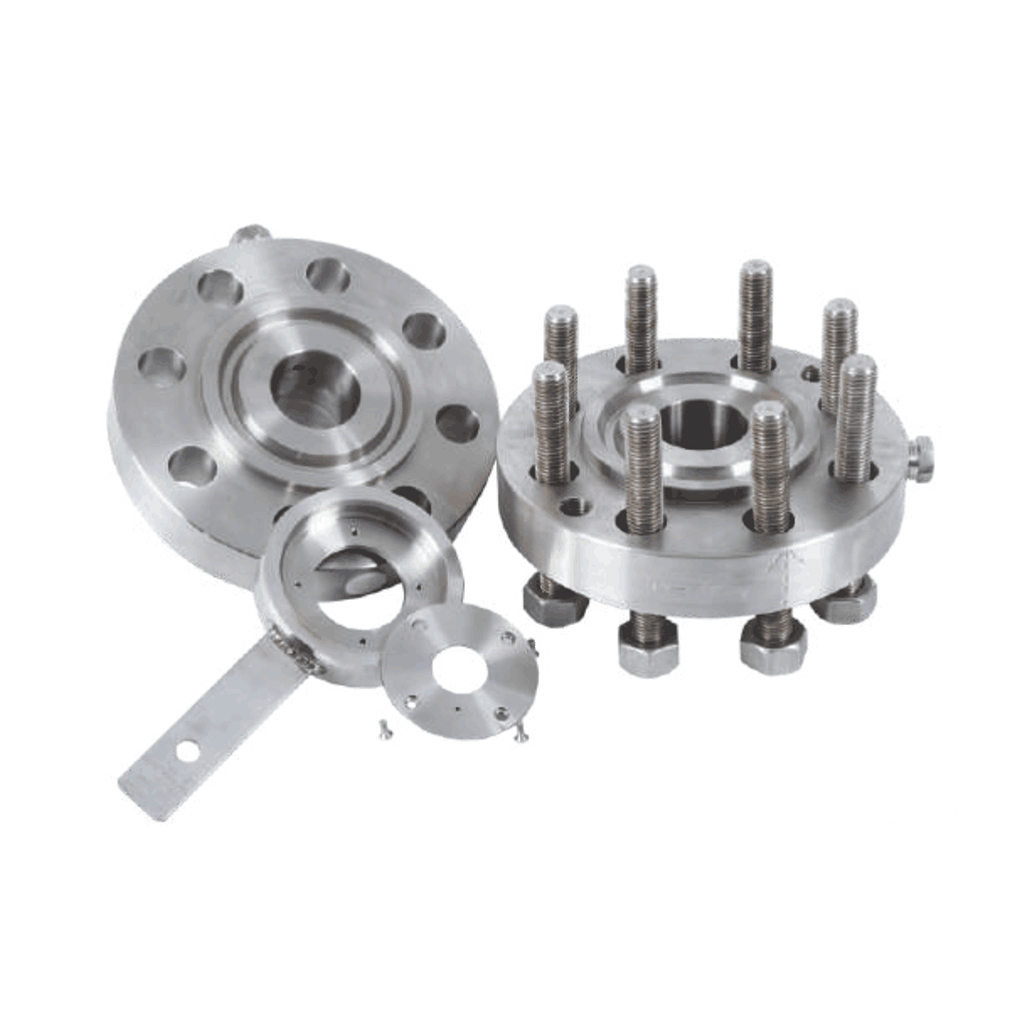

The Plate Holder Assembly is a combination of plate holder and an orifice plate designed for ring tongue joint (RTJ) flanges. The plate holder has a function of holding the orifice plate and also a function as a gasket to prevent leakage of the process fluid. The plate holder has a oval or octagonal ring for mounting between ring tongue joint flanges. This metallic sealing system is applicable to a fluid of high temperature and high pressure. The pressure tapping system normally is of the flange tap type.

Orifice plate is screwed to the plate holder. Generally the plate holder is of soft iron material. The Orifice plate is available in standard material such as SS316, SS304, SS316L, Monel, Hastelloy-C, etc. Other materials are available on request. The plate holder along with the orifice plate can be also machined from one piece.

RTJ holder material is selected so that the RTJ holder hardness is less than that of flange hardness.

Routine tests:

a) PMI Test

b) Calibration

c) NACE

d) HIC Test

Specifications:

- Design : Conforms to ISA RP 3.2

- Types : Square edge concentric, Quadrant edged, Conical entrance, Eccentric, Segmental

- Plate material : SS304 , SS316 , SS316L as standard. Hastelloy-C , Monel , PP , PVC , PTFE coated , etc. can be given on request.

- Orifice Bore : In accordance with ISO- 5167, BS-1042, ASME MFC 3M, R.W.Miller, L.K.Spink, AGA-3

- Tab Plate : In the same material as plate & is welded to orifice plate. Tab plate integral to the Orifice plate (i.e. without welding) can also be offered as a special case.

- Vent / Drain : Vent or Drain holes are provided as per customer’s requirement. The diameter of the vent or drain holes are as per ISA RP 3.2

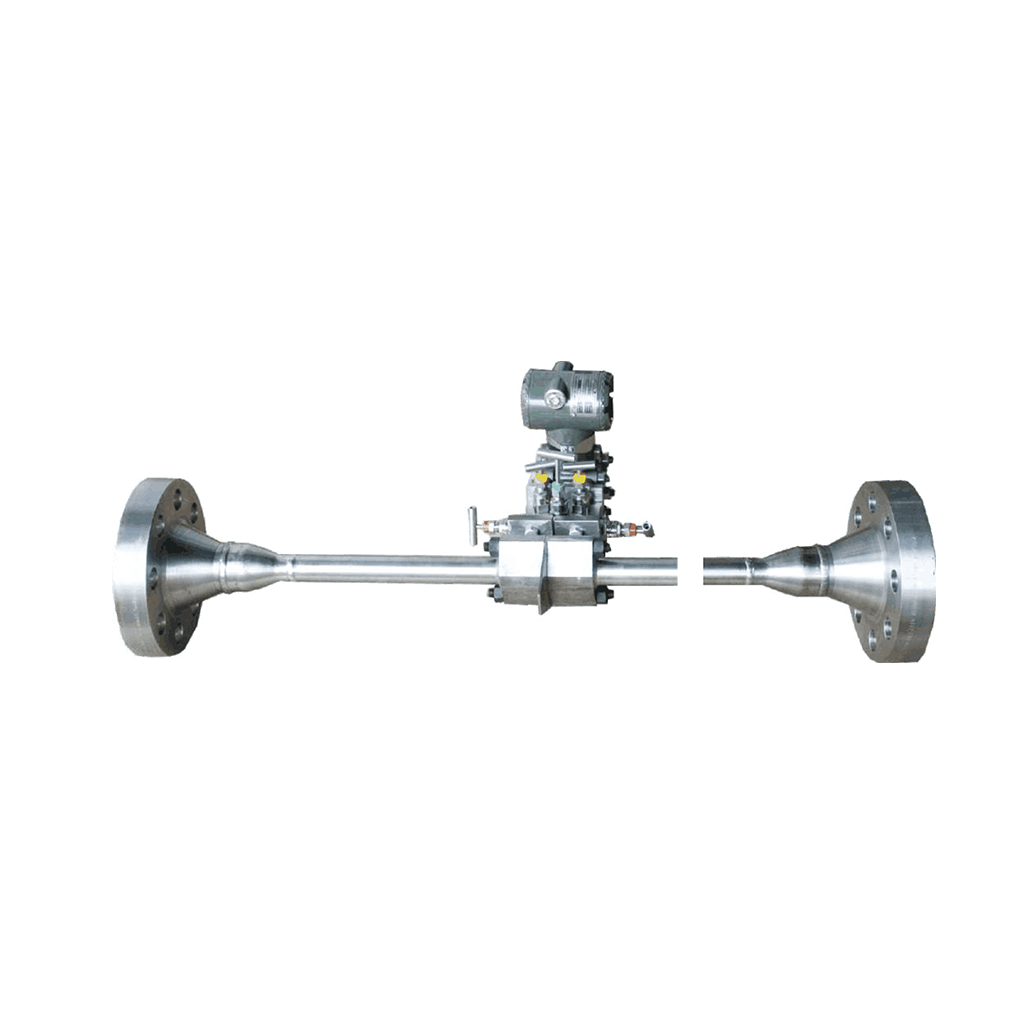

- Flange Union : Weld neck, Slip on, Threaded, Socket welded with RF or RTJ facing Orifice flanges are in accordance with ANSI B16.36 with minimum flange rating of 300# for sizes up to 8” or male – female flanges in accordance with ANSI B16.5.

- Pressure Tappings : Corner tappings are recommended for sizes upto 1.5; Flange taps from 2″ to 16″ D – D/2 taps for higher sizes.

- Gasket : SS spiral wound + Grafoil, SS spiral wound + PTFE are normally supplied as per process requirement. Other materials available on request. For RTJ flanges , the plate is fixed on the plate holder. The plate holder material will be softer than flange material & acts as a gasket .

- Studs / Nuts : ASTM A193 Gr.B7/A-194 Gr.2H as standard, Other material on request.

- Jack Screw : ASTM A193 Gr.B7/A-194 Gr.2H as standard, Other material on request.