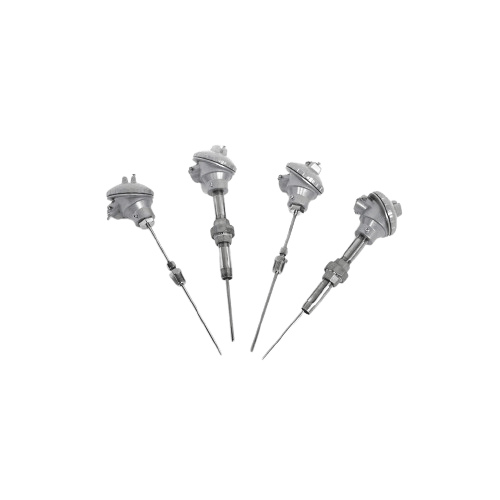

General Instruments Nickel Wire Mineral Insulated RTD

GIC is the leading Nickel Wire Mineral Insulated RTD Manufacturer in India providing reliable solutions for accurate temperature measurement to process industry worldwide.

In continuation with its endeavour to provide products of the best quality to clients, General has developed RTD with Nickel conductors in Mineral Insulated Construction for the first time in India. The basic difference between conventional and nickel conductors is the material of the conductor. In conventional, it is copper as against Nickel in newly developed MI.

Routine tests:

a) Accuracy/Calibration Test

b) Nitrogen Leakage Test (Weld

Closure Conformity)

c) Insulation Resistance Test

d) Thermal Response Time Test

e) Continuity Test

f) Dimension Checks

Type tests:

a) Vibration test

b) Drop / Shock test

c) Self-heating error test

d) Hysteresis Test

e) Stability Test

f) Autoclave Test

g) Pull Test (Load Withstand Test)

h) Di-electric strength Test (H.V. Test)

Advantages:

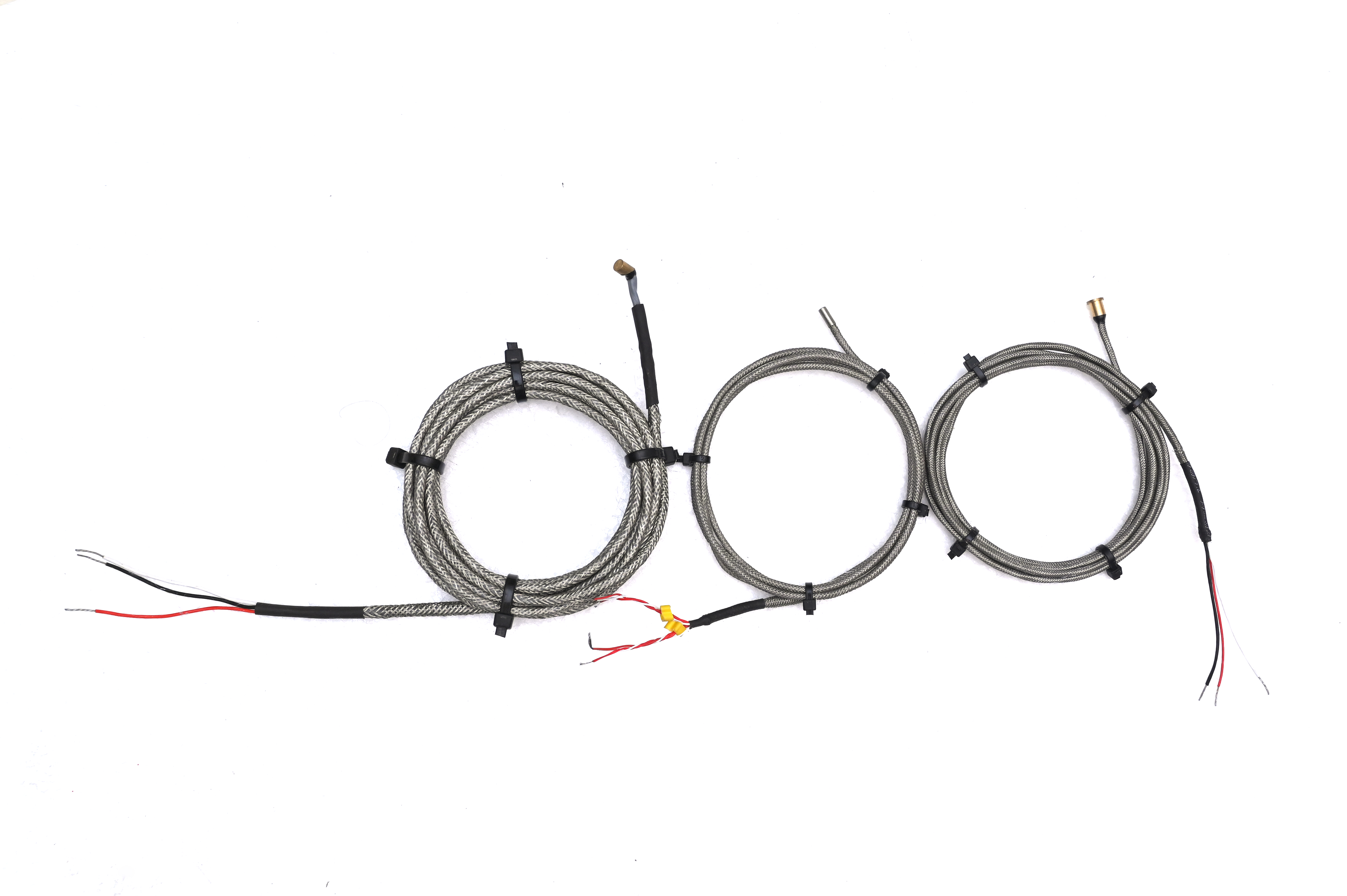

- Most important advantage is that the RTD element is welded on to conductors and not brazed. As such same RTD can be used for much higher temperature of up to 600°C. In conventional RTD with copper conductor, brazing does not allow use of RTD above 450°C, after which brazing starts softening and RTD loses its contact with cable conductors. In Nickel conductors, as Nickel can be welded, contact is much more stronger even at a higher temperature.

- Nickel conductor cables are annealed at higher temperature than that of Copper. The cable therefore is much more softer. Hence RTDs made with nickel conductor are more pliable and easier to use.

- Nickel has much more strength than copper. Hence, they can be directly terminated in the terminal block avoiding another connection of flexible leads. RTDs with Nickel conductors give steady readings and chances of loose connection of flexible leads to copper wires is avoided.

- As Nickel conductors are welded to RTD element, it is a much more stable design than brazed RTD. This advantage is very important in applications where vibrations are present.

- Copper can get easily oxidised causing fluctuations in readings. Nickel being much more inert chemically, is not so prone to oxidation and hence gives stable readings over a longer period of time.