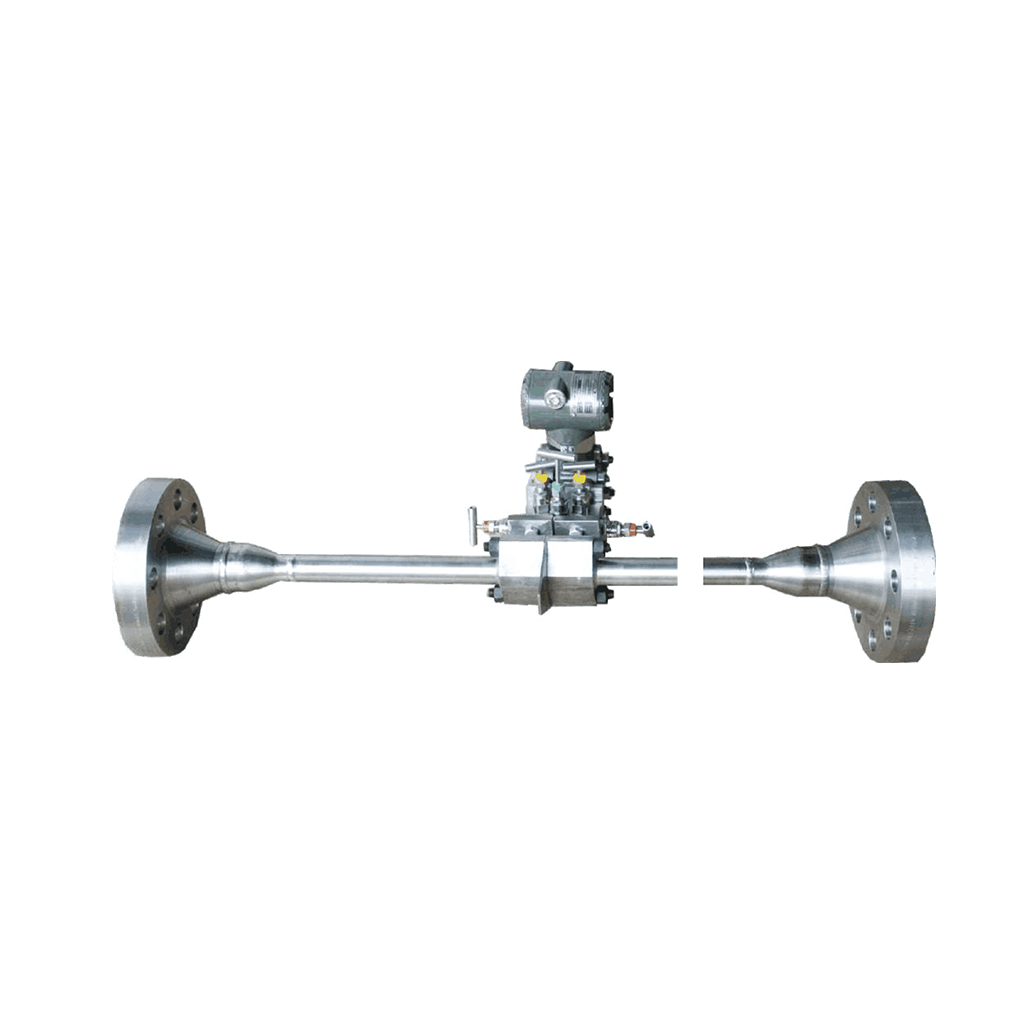

General Instruments Orifice Plate

GIC is the leading Orifice Plate Manufacturer in India providing reliable solutions for accurate pressure measurement to process industry worldwide.

Orifice plates are the most commonly used primary elements for flow measurement in pipelines based on the principle of measurement of ‘differential pressure’ created when an obstruction is placed in the fluid flow, due to an increase in fluid velocity. Orifice Plates cover a wide range of applications of fluid and operating conditions. They give an acceptable level of uncertainty at the lowest cost and long life without regular maintenance.

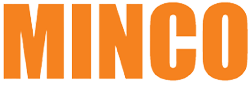

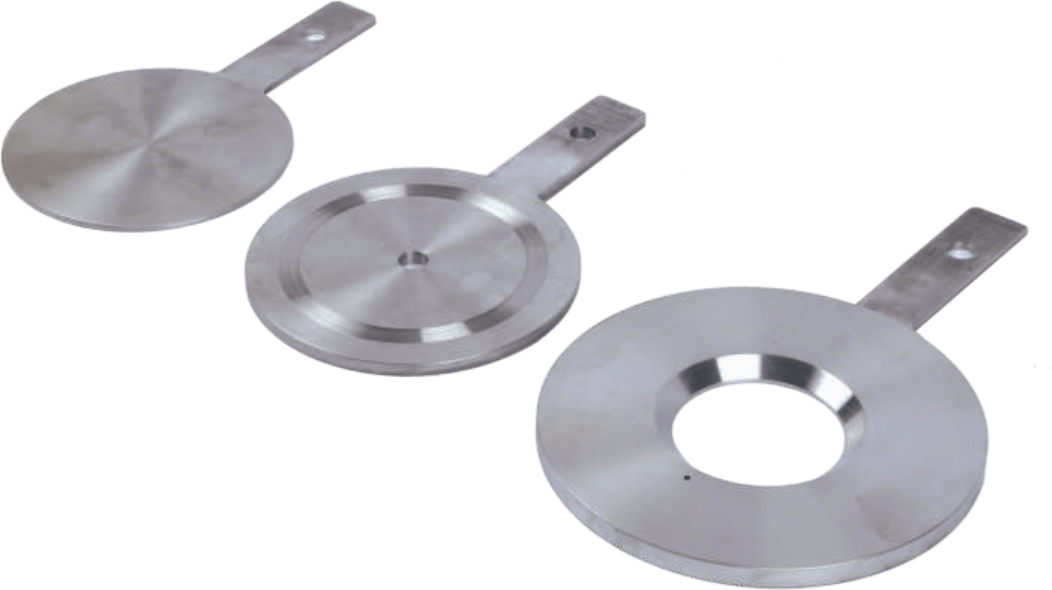

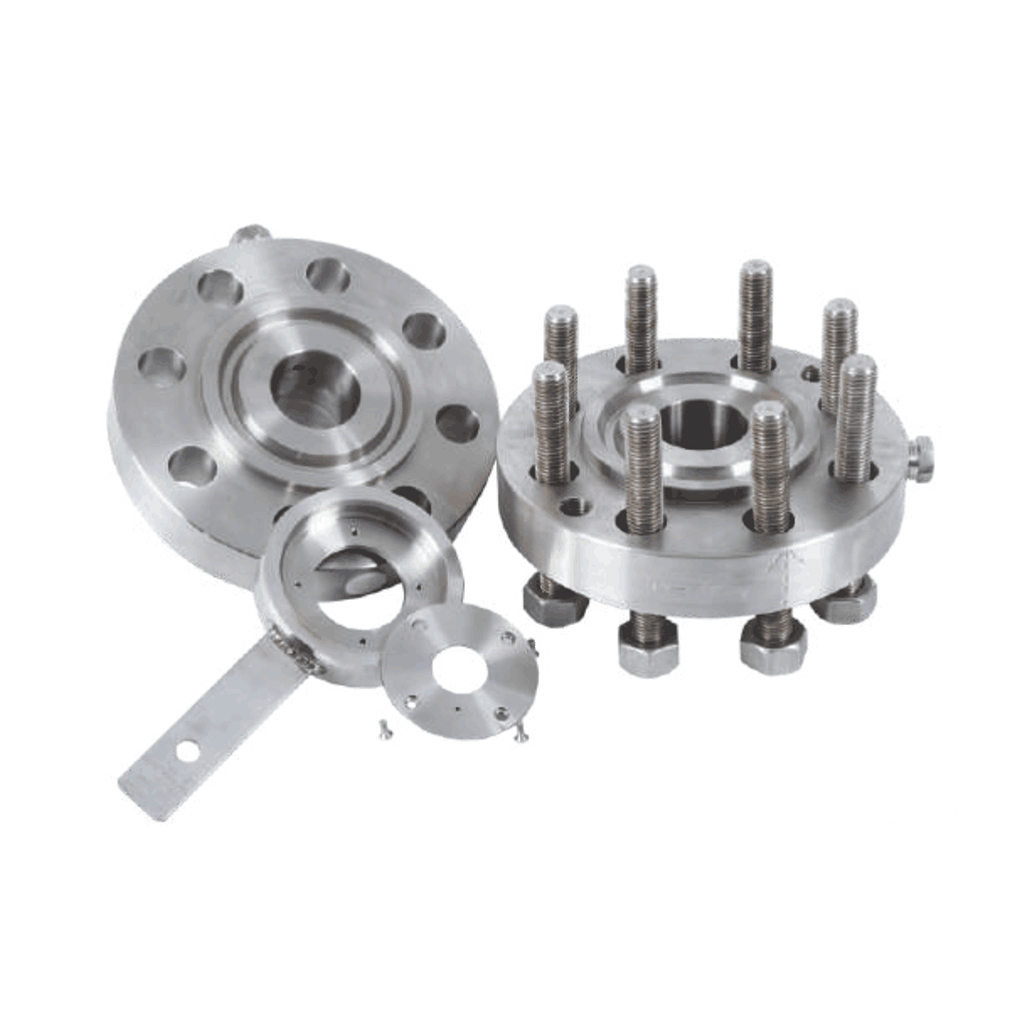

We manufacture orifice plates, restriction orifice plates, with or without carrier rings, meter run assemblies, and integral orifice plates to suit customer’s requirements. We have fully equipped integrated designing, manufacturing, and testing facilities that are among the best in the country. Over the years we have manufactured and supplied orifice plate assemblies to many prestigious projects in the domestic as well as international market.

Routine tests:

a) PMI Test

b) NACE

Specifications:

- Design : Conforms to ISA RP 3.2

- Types : Square edge concentric, Quadrant edged, Conical entrance, Eccentric, Segmental

- Plate material : SS304 , SS316 , SS316L as standard. Hastelloy-C , Monel , PP , PVC , PTFE coated , etc. can be given on request.

- Orifice Bore : In accordance with ISO- 5167, BS-1042, ASME MFC 3M, R.W.Miller, L.K.Spink, AGA-3

- Tab Plate : In the same material as plate & is welded to orifice plate. Tab plate integral to the Orifice plate (i.e. without welding) can also be offered as a special case.

- Vent / Drain : Vent or Drain holes are provided as per customer’s requirement. The diameter of the vent or drain holes are as per ISA RP 3.2

- Flange Union : Weld neck, Slip on, Threaded, Socket welded with RF or RTJ facing Orifice flanges are in accordance with ANSI B16.36 with minimum flange rating of 300# for sizes up to 8” or male – female flanges in accordance with ANSI B16.5.

- Pressure Tappings : Corner tappings are recommended for sizes upto 1.5; Flange taps from 2″ to 16″. D – D/2 taps for higher sizes.

- Gasket : SS spiral wound + Grafoil, SS spiral wound + PTFE are normally supplied as per process requirement. Other materials available on request. For RTJ flanges , the plate is fixed on the plate holder. The plate holder material will be softer than flange material & acts as a gasket.

- Studs / Nuts : ASTM A193 Gr.B7/A-194 Gr.2H as standard, Other material on request.

- Jack Screw : ASTM A193 Gr.B7/A-194 Gr.2H as standard, Other material on request.