General Instruments Multi Hole Plate

GIC is the leading Orifice Plate Manufacturer in India providing reliable solutions for accurate pressure measurement to process industry worldwide.

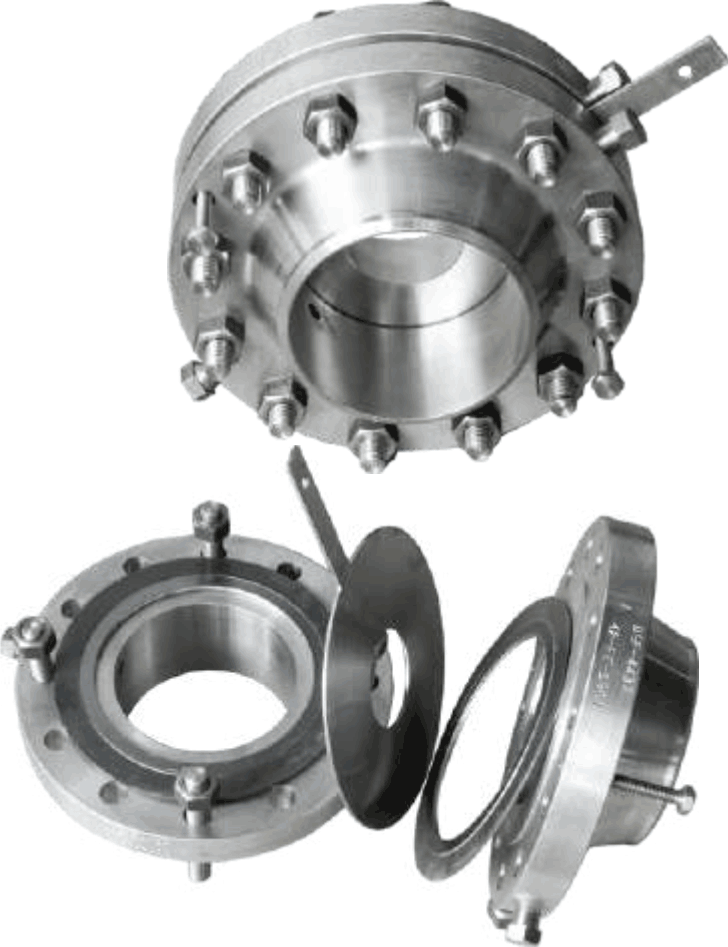

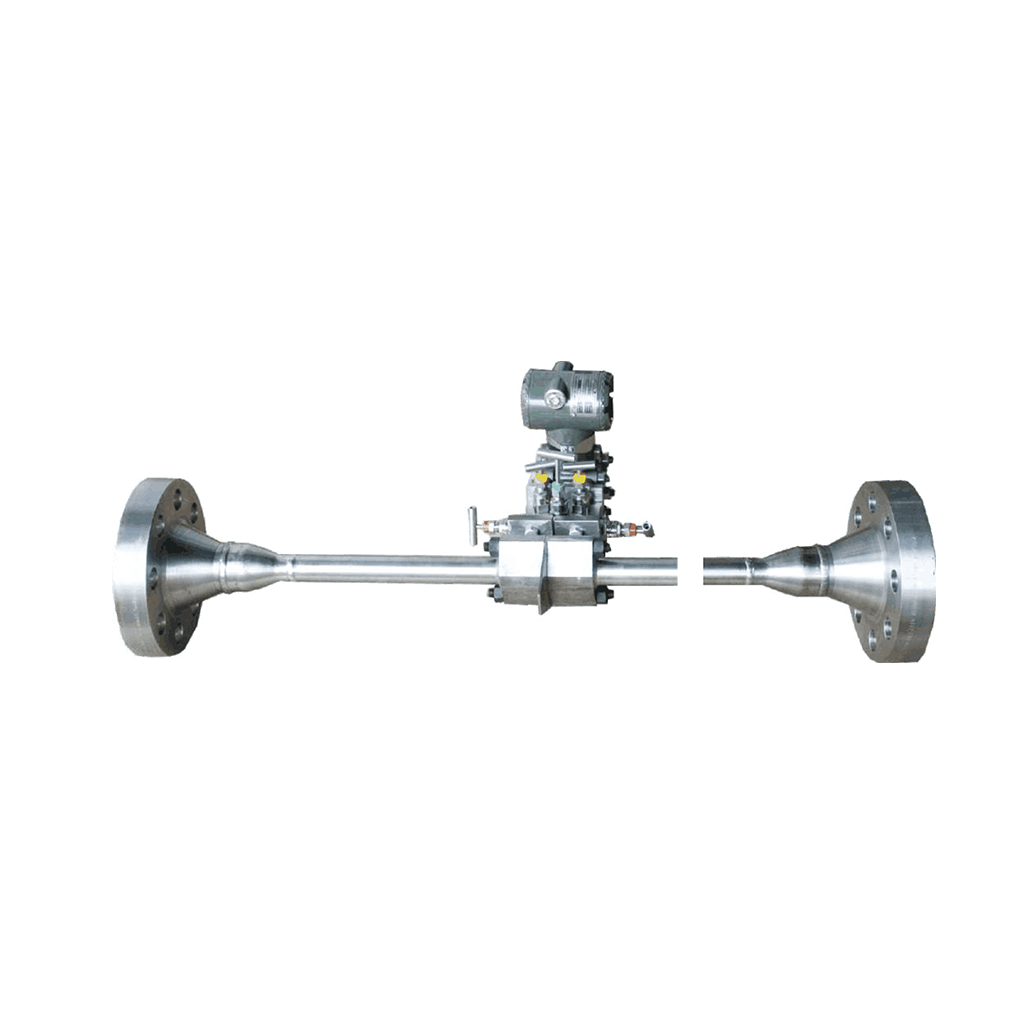

Multi-hole Orifice plate is our new development in flow elements. These plates are used in low straight length availabilities.

Multi-hole plate is having 4 numbers of holes placed in between the flow area at certain distance. These 4 holes itself act as a flow conditioner thereby reducing the straight length requirement to Maximum 3D upstream and 2D downstream at any given beta ratio.

Multi-hole orifice plates are suitable for most of the fluids including, steam, air or any type of gas and any type of liquids (preferably lesser visocous liquids) etc. Accuracy for Multi-hole orifice plates is even better than the conventional orifice plates and the same is upto 0.4%. Due to conditioning effect turndown ratio of the Multi-hole Orifice plates increases to 10 : 1.

Installation for these plates is same as per the conventional orifice plates. Multi-hole orifice plates can be used with Corner & Flange tapping.

We can provide Multi-hole plates in almost all material compositions including Stainless Steel, Hastelloy-C, Monel & Titanium etc.

Routine tests:

a) PMI Test

b) NACE

Specifications:

- Design : Conforms to ISA RP 3.2

- Types : Square edge concentric, Quadrant edged, Conical entrance, Eccentric, Segmental

- Plate material : SS304 , SS316 , SS316L as standard. Hastelloy-C , Monel , PP , PVC , PTFE coated , etc. can be given on request.

- Orifice Bore : In accordance with ISO- 5167, BS-1042, ASME MFC 3M, R.W.Miller, L.K.Spink, AGA-3

- Tab Plate : In the same material as plate & is welded to orifice plate. Tab plate integral to the Orifice plate (i.e. without welding) can also be offered as a special case.

- Vent / Drain : Vent or Drain holes are provided as per customer’s requirement. The diameter of the vent or drain holes are as per ISA RP 3.2

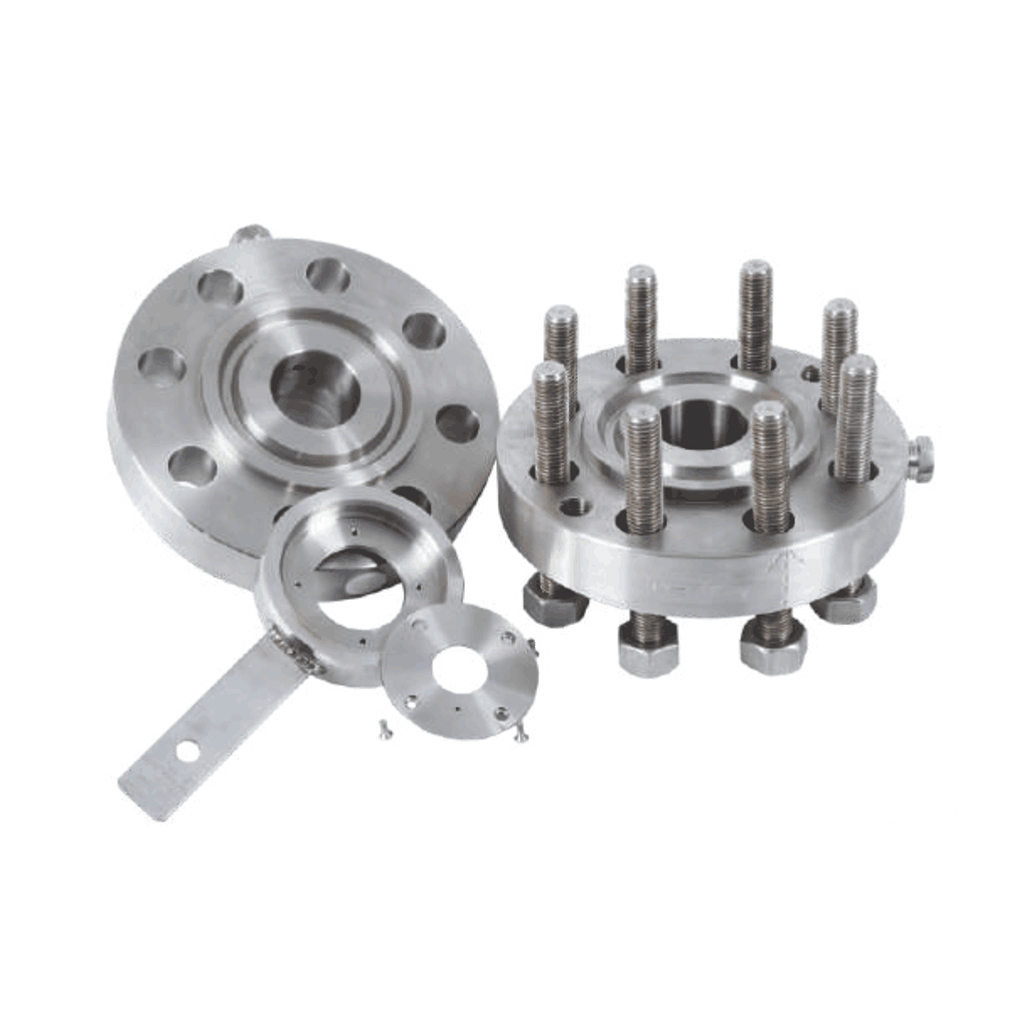

- Flange Union : Weld neck, Slip on, Threaded, Socket welded with RF or RTJ facing Orifice flanges are in accordance with ANSI B16.36 with minimum flange rating of 300# for sizes up to 8” or male – female flanges in accordance with ANSI B16.5.

- Pressure Tappings : Corner tappings are recommended for sizes upto 1.5; Flange taps from 2″ to 16″; D – D/2 taps for higher sizes.

- Gasket : SS spiral wound + Grafoil, SS spiral wound + PTFE are normally supplied as per process requirement. Other materials available on request. For RTJ flanges , the plate is fixed on the plate holder. The plate holder material will be softer than flange material & acts as a gasket .

- Studs / Nuts : ASTM A193 Gr.B7/A-194 Gr.2H as standard, Other material on request.

- Jack Screw : ASTM A193 Gr.B7/A-194 Gr.2H as standard, Other material on request.