Helicoidal Thermowells: Solving Vortex-Induced Vibrations in High-Velocity Lines

Introduction:

In the world of process temperature monitoring and control, traditional cylindrical thermowells have long been plagued by a phenomenon known as vortex-induced vibrations (VIV). These vibrations occur as the fluid flow passes the thermowell, leading to potential equipment and thermowell failures. However, there’s a groundbreaking solution that is changing the game – the Helicoidal Well thermowell. In this blog, we delve into the unique features and advantages of the Helicoidal Well design, and how it addresses the challenges posed by VIV in high-velocity lines.

The Problem with Traditional Thermowells: Vortex-Induced Vibrations (VIV)

Traditional cylindrical thermowells are susceptible to vortex-induced vibrations (VIV) due to the formation of vortices in the wake of the thermowell stem. When the frequency of these vortices aligns with the thermowell’s natural frequency, catastrophic failures can occur. This is a significant concern, especially in high-velocity flow lines.

Introducing Helicoidal Well Thermowells: An Innovative Solution

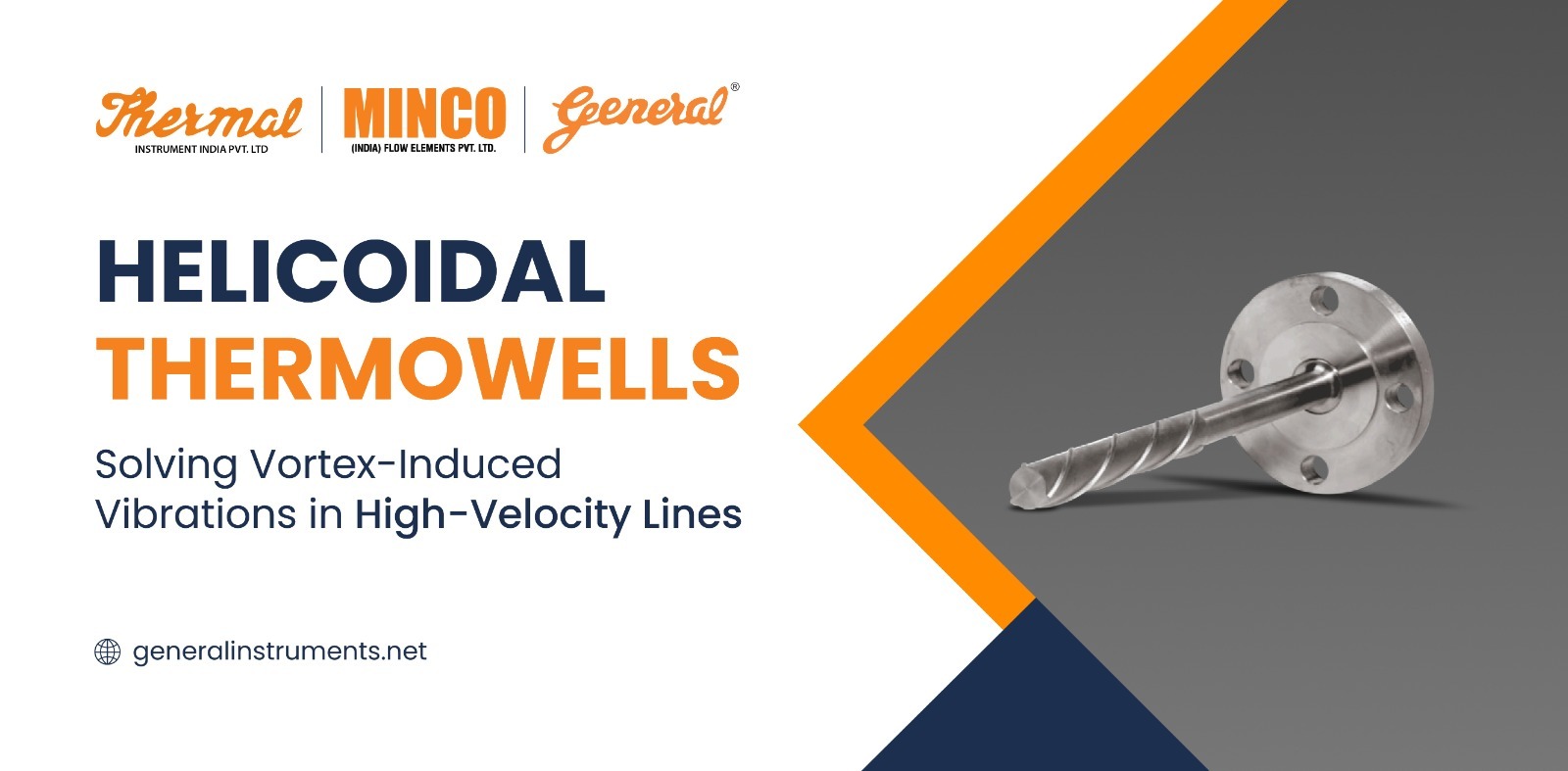

The Helicoidal Well thermowell is a revolutionary solution designed to eliminate the challenges posed by vortex-induced vibrations. This solid drilled thermowell features a unique helical strake design, inspired by the helical strakes found on columns and cooling towers. This innovative design effectively eliminates the need for velocity collars and enhances the safety and accuracy of process temperature measurements.

Advantages of Helicoidal Well Thermowells:

- Elimination of Vortex Effect: The helical strake design disrupts the formation of large vortices, significantly reducing the risk of vortex-induced vibrations.

- Quick Response Time: The elimination of the vortex effect allows for a reduction in wall thickness, leading to faster and more accurate temperature response times.

- ASME PTC 19.3 TW 2016 Compliant: Helicoidal Well thermowells are designed around the industry standard ASME PTC 19.3 TW 2016 Wake Frequency calculation, ensuring compliance with rigorous safety standards.

- Offshore-Focused Design: The design and construction of Helicoidal Well thermowells are tailored for offshore applications, where reliability and safety are paramount.

- Technical Breakdown: Helicoidal Well vs. Standard Thermowell Design

- Standard Cylindrical Thermowell: Vortices produced in the wake of the thermowell stem can lead to vortex-induced vibrations when their frequency aligns with the thermowell’s natural frequency.

- Helicoidal Thermowell: The helical strake design generates smaller, non-uniform vortices that do not resonate with the thermowell’s natural frequency. This eliminates the risk of vortex-induced vibrations.

Illustrative Examples:

- Standard Thermowell Design: In certain flow conditions, a Kármán vortex street can form behind the thermowell stem, inducing vibrations and potential failures.

- Helicoidal Thermowell Design: Helical coils disrupt the flow, preventing the formation of a well-defined Kármán vortex street and reducing vibrational excitation.

Conclusion:

In the realm of process temperature monitoring and control, the Helicoidal Well thermowell stands as an innovative solution to the age-old problem of vortex-induced vibrations. By incorporating a helical strake design, this thermowell effectively eliminates the need for velocity collars, enhances response times, and ensures compliance with industry standards. With the Helicoidal Well design, industries can mitigate the risks associated with poor thermowell design and confidently operate high-velocity lines without fear of catastrophic failures.