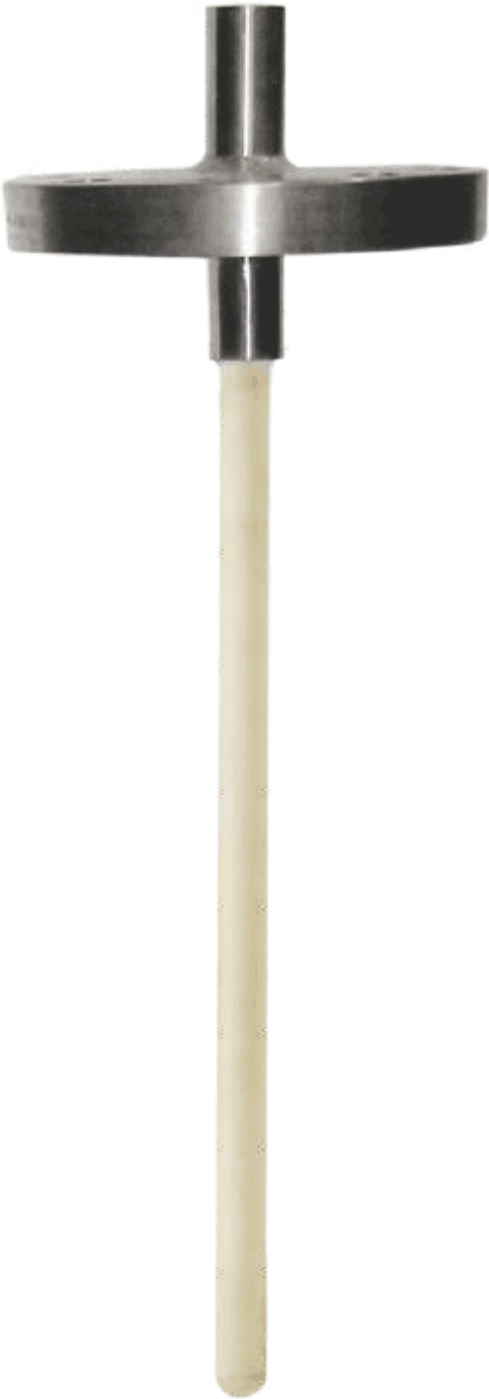

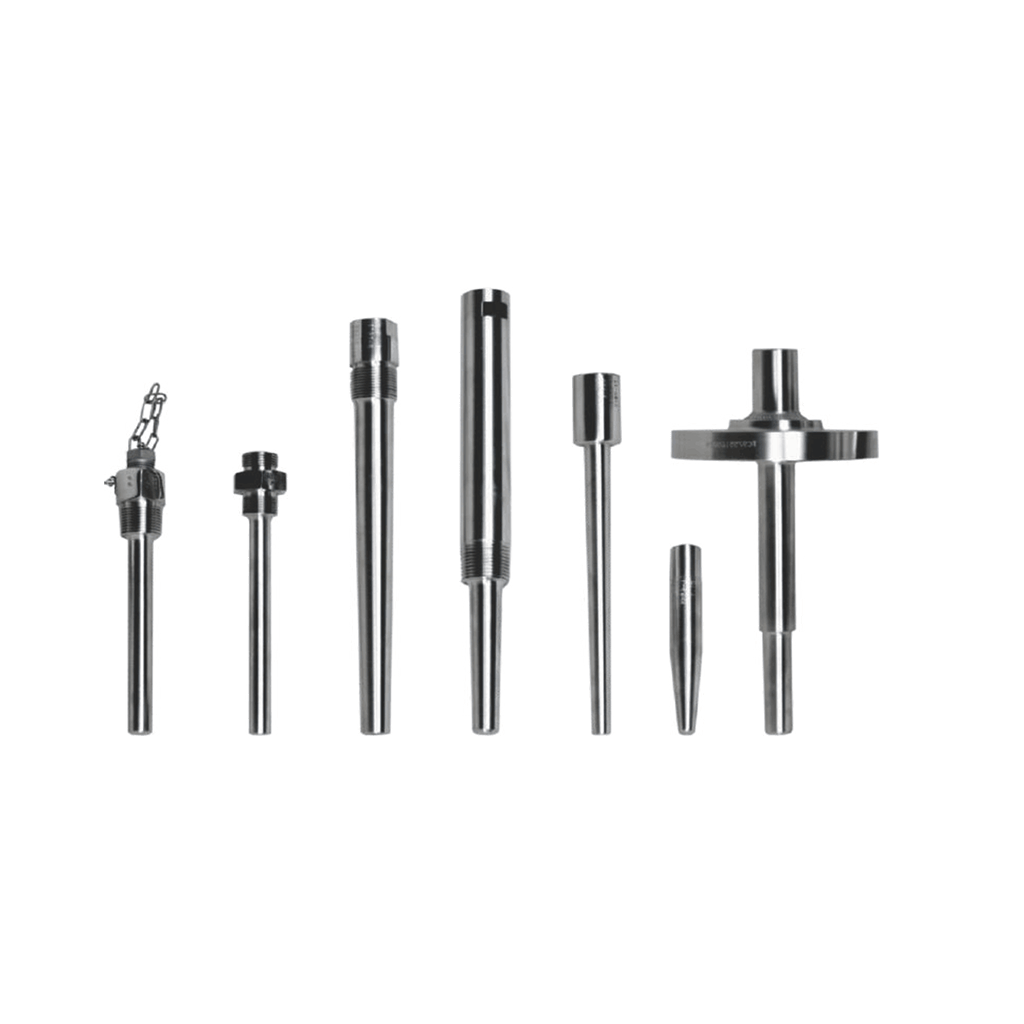

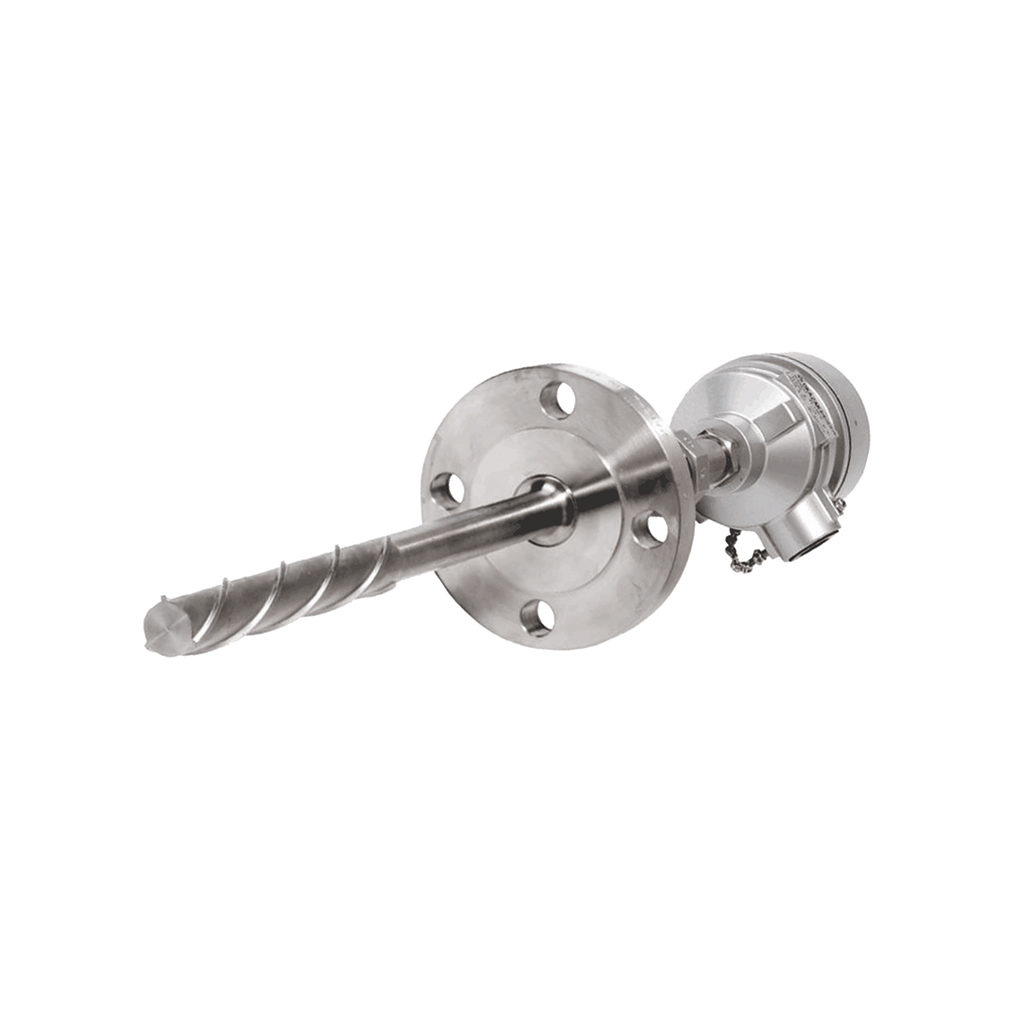

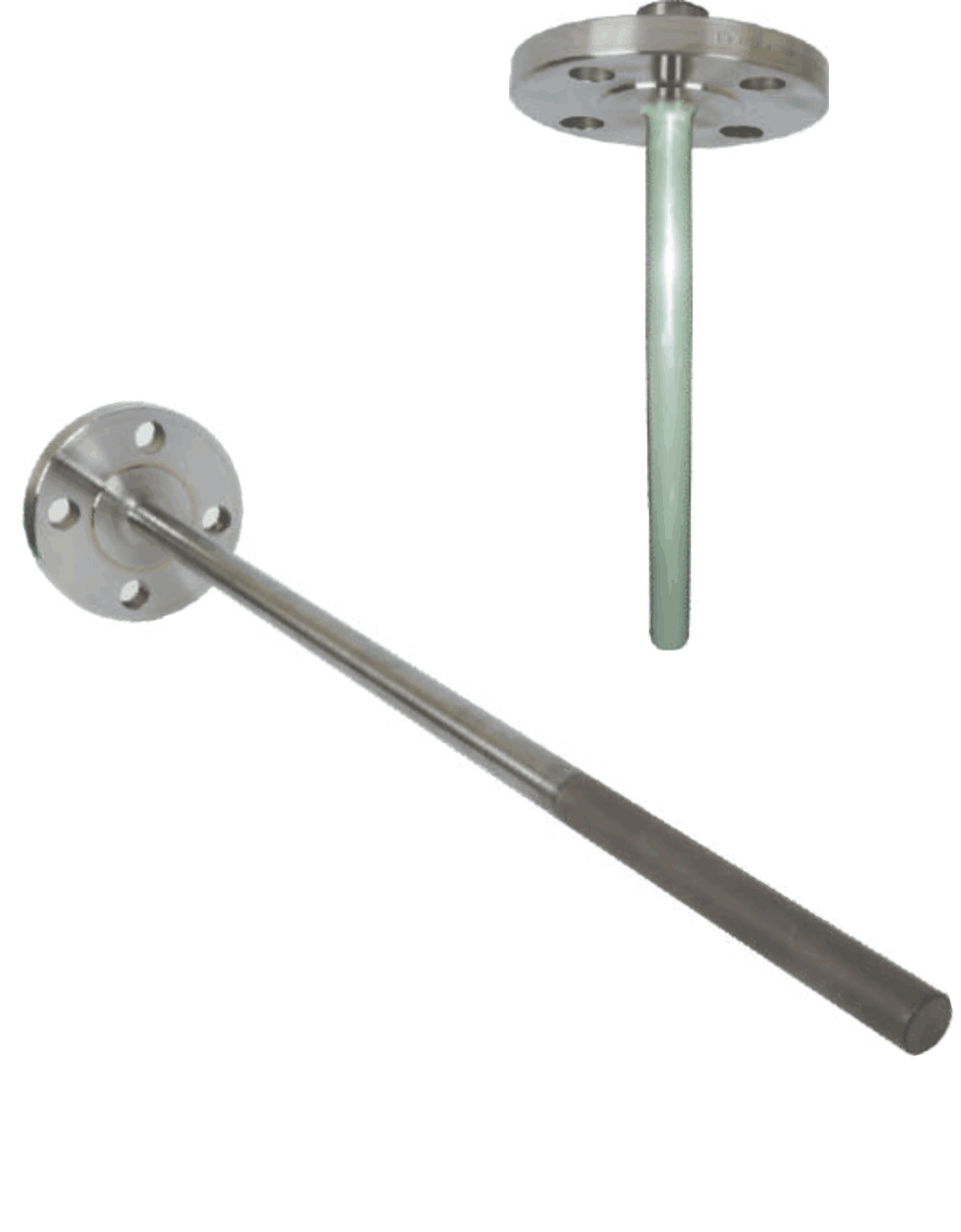

General Instruments Ceramic / Hexoloy Thermowells for high temperature application

GIC is the leading Ceramic / Hexoloy Thermowells for high temperature application Manufacturer providing Reliable Solutions for Accurate Temperature Measurement to the Process Industry worldwide.

For high temperature applications, generally, Ceramic protecting tubes are used in different industries such as Iron & Steel, glass, cement etc. It has high resistance to thermal shocks. It is inert to most chemicals and has a high dielectric strength. These are primarily used to protect noble metal thermocouples (like R, S & B type) They are available in variety of sizes. Normally it is cemented (by high temperature withstanding cement) to metal tubes (which are termed as holding tubes). The process connection slides or is welded to this metallic portion of the tube. For double protection, inner ceramic tube is also used. Mainly two grades of ceramic are used. Ceramic 610 (also termed as Mullite) & Ceramic 710 (recrystallized 0 0 Alumina-99.5% purity) can withstand up to 1500 C & 1800 C respectively. It should be remembered that it has poor mechanical shock resistance. It is impervious to gases at high temperatures

Routine tests:

- Dimension Check

- Hydro Test

- Dye Penetration Test

- Bore Concentricity Check

- Pneumatic Test on Sleeves

Optional Tests :

- Positive Material Identification (PMI) Test

- Helium Leakage Test

- Radiography Test

- NACE MR 0175 / 0103 / ISO 15156

- Corrosion Tests

- FN Test

- MPT

- Impact Test

- UT test

- Ultrasonic Cleaning

- Oxygen Cleaning

Raw Material Testing

- Chemical & Physical Properties

- Hardness Test

- Micro Test

- Microstructure Analysis

Specifications:

Silicon Carbide protecting tubes are also used generally as a secondary protection for applications such as Kilns, Furnaces, Stove Dome etc. Recrystallised silicon carbide has a very high abrasion resistance. Also used for flue gas application or 0 incinerators in waste management system. It can withstand 1600 C & direct flame impingement. It is extremely hard & chemically inert. It resists most of the acids, molten salts. Generally used in conjunction with ceramic tube. Cermet (LT-1) which is metal ceramic composite (combination of chromium & 0 aluminium oxide) is stable in oxidising atmospheres upto 1300 C. Cermet tubes are stronger & more resistant to thermal & mechanical shocks than ceramic protecting tubes. Main area of usage is in molten copper, open hearth furnace, blast furnace. Ceramic primary tube is recommended when Cermet is used.